Understanding Allen-Bradley's PanelView and FactoryTalk Optix Platforms

March 21st, 2025

4 min read

In industrial automation, there’s no such thing as a one-size-fits-all approach, especially when it comes to Human-Machine Interface (HMI) systems. The right HMI doesn’t just display data; it shapes how your team interacts with your machines, makes decisions, and responds to unexpected issues. As manufacturers race to modernize and connect their operations, HMI platforms have taken on a much larger role than they played even a decade ago.

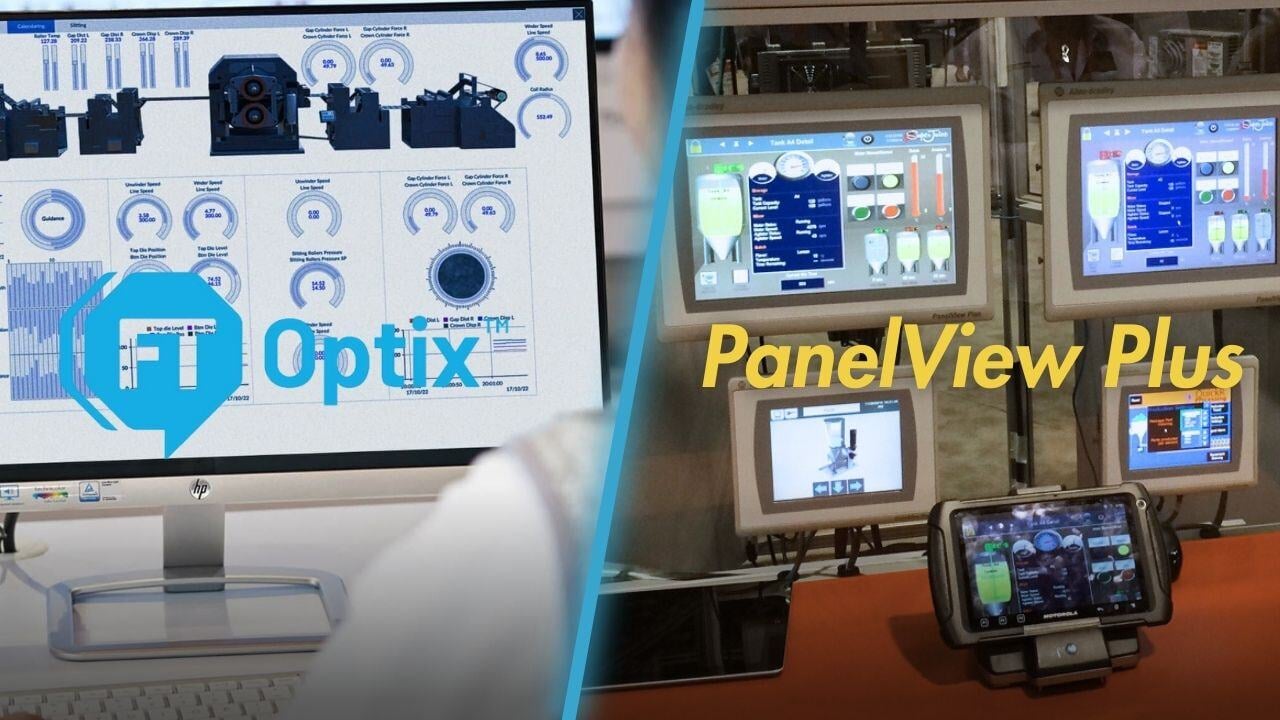

That brings us to two major options from Rockwell Automation: PanelView and FactoryTalk Optix. Both are powerful, both are built by Allen-Bradley, and both are actively used in industrial environments across the globe. But they were built for very different use cases—and choosing the wrong one can lead to unnecessary frustration, underutilized capabilities, or compatibility headaches.

At HESCO, we help facilities like yours navigate these choices every day. Whether you're upgrading legacy systems or designing a next-gen production line, understanding how these platforms differ is key to choosing the one that aligns with your operational goals, not just today, but five years down the line.

PanelView: The Industry Standard Built for Reliability

A PanelView Plus 7 interface

First launched in 1989, PanelView has earned its place as a staple on plant floors across the country. It’s dependable, rugged, and known for its tight integration with Allen-Bradley control systems. You’ll find PanelView HMIs embedded in food and beverage facilities, water treatment plants, packaging lines, and other high-demand environments where downtime isn’t an option.

The PanelView family includes several different models tailored to a range of use cases. PanelView Plus is typically the choice for complex applications requiring robust visualization, connectivity, and control.

For facilities that are already heavily invested in the Studio 5000 ecosystem, the PanelView 5000 offers tighter Logix controller integration and improved performance. On the other end of the spectrum, the PanelView 800 is a great fit for simpler machine-level applications, especially where cost and footprint are considerations.

PanelView devices are built to withstand tough environments. With high IP ratings, wide temperature tolerances, and touchscreen displays that stand up to dust, grease, and vibration, they’re designed for industrial settings that push other hardware to its limits.

Software-wise, PanelView leans into Rockwell's broader ecosystem. Depending on your hardware, you’ll use FactoryTalk View Studio, Connected Components Workbench, or Studio 5000 View Designer to build your HMI screens.

While these tools are powerful, they also come with a learning curve, so they’re best suited for teams that are already fluent in Rockwell’s automation platforms.

FactoryTalk Optix: Rockwell’s Vision for the Connected Future

The FactoryTalk Optix studio interface

If PanelView is the tried-and-true classic, FactoryTalk Optix is the next-generation alternative, engineered for a world that’s more connected, data-driven, and flexible than ever before. It’s Rockwell Automation’s answer to the growing demand for cloud connectivity, remote access, and platform openness.

Unlike PanelView, which is tightly tied to Allen-Bradley PLCs, Optix was designed from the ground up to support open protocols and third-party devices. It natively supports OPC UA, which means it can talk to a wide variety of industrial systems, regardless of manufacturer. That flexibility makes it a strong fit for facilities with diverse equipment or those planning to expand beyond a single vendor.

One of the biggest differences is how Optix is developed and deployed. Instead of installing software on a specific workstation, OptixStudio lives in your web browser. This allows your team to build, test, and update applications from anywhere, whether they’re on the plant floor or across the country.

Because it’s built with drag-and-drop development tools, Optix can be more accessible for users without formal HMI programming experience. And since it's cloud-capable, updates and diagnostics can be done remotely, cutting down on the time it takes to respond to issues or deploy system-wide changes.

Feature-wise, FactoryTalk Optix leans heavily into real-time visibility and advanced data handling. You’ll find support for high-resolution graphics, smooth animations, and advanced dashboarding features that make complex information easier to understand at a glance.

Optix includes built-in recipe management, comprehensive data logging capabilities, and seamless integration with safety tools and analytics platforms. And it’s all designed to scale, from single-machine operations to enterprise-wide monitoring systems.

PanelView vs. Optix: Where Each Platform Excels

While both platforms have their strengths, they serve different goals. PanelView is built for stability and long-term reliability. It’s the logical choice for facilities that already rely on Allen-Bradley hardware and don’t need cloud or remote capabilities. If you're upgrading existing HMIs or want something that integrates seamlessly with Studio 5000 and ControlLogix, PanelView offers a familiar and proven solution. It’s also ideal for facilities with strict IT policies that limit internet connectivity or cloud deployments.

On the other hand, FactoryTalk Optix is designed for agility. It’s best suited for teams with a forward-looking mindset investing in centralized monitoring, remote support, or predictive maintenance strategies. Facilities that manage multiple locations or work with a variety of vendor technologies will appreciate Optix’s interoperability and cloud-first capabilities. And for organizations looking to streamline HMI development or empower less technical users, OptixStudio offers a more intuitive, user-friendly experience.

What Should Drive Your Decision?

Choosing between PanelView and Optix comes down to understanding where your facility stands and where it’s headed.

Start by taking stock of your infrastructure. If your entire system is already Allen-Bradley from top to bottom, PanelView may still be the best path forward. The integration is seamless, the software tools are battle-tested, and support is readily available. But if you’re in a mixed-vendor environment or anticipate needing more flexibility soon, Optix’s open architecture might be the smarter long-term investment.

Next, consider your team. Who will be building and maintaining these HMIs? If you’ve got a crew of Rockwell-savvy engineers, PanelView may fit right into your workflow. But if your team includes IT pros, OEM partners, or cross-functional stakeholders, Optix’s browser-based development and easier learning curve can open up new opportunities for collaboration and efficiency.

And finally, think about the kind of access and insights your operation demands. PanelView is a great solution for machine-level visibility and local control. But if your team needs to monitor systems across facilities, pull real-time data from remote locations, or feed production insights into cloud analytics platforms, then Optix was built with your goals in mind.

The Bottom Line: It’s About More Than Hardware

At the end of the day, selecting the right HMI platform is about more than picking a piece of hardware or a development tool. It’s about choosing a foundation for how your team works. Your HMI is the first thing operators touch, the first place engineers look for insight, and the interface that connects your production floor to your business decisions.

PanelView delivers a rock-solid, integrated experience for facilities that value stability and proven performance. FactoryTalk Optix offers the flexibility, scalability, and connectivity that modern manufacturers need to stay competitive in a data-driven world.

Whichever direction you’re leaning, we’re here to help. At HESCO, we don’t just sell the parts; we help you design the strategy. If you’re not sure which platform is right for your next project, let’s talk. We can walk through your goals, audit your current systems, and help you find the solution that fits both your present-day needs and your long-term plans.