Received the “Same” Part with a Different Label? Here's What It Means

May 28th, 2025

3 min read

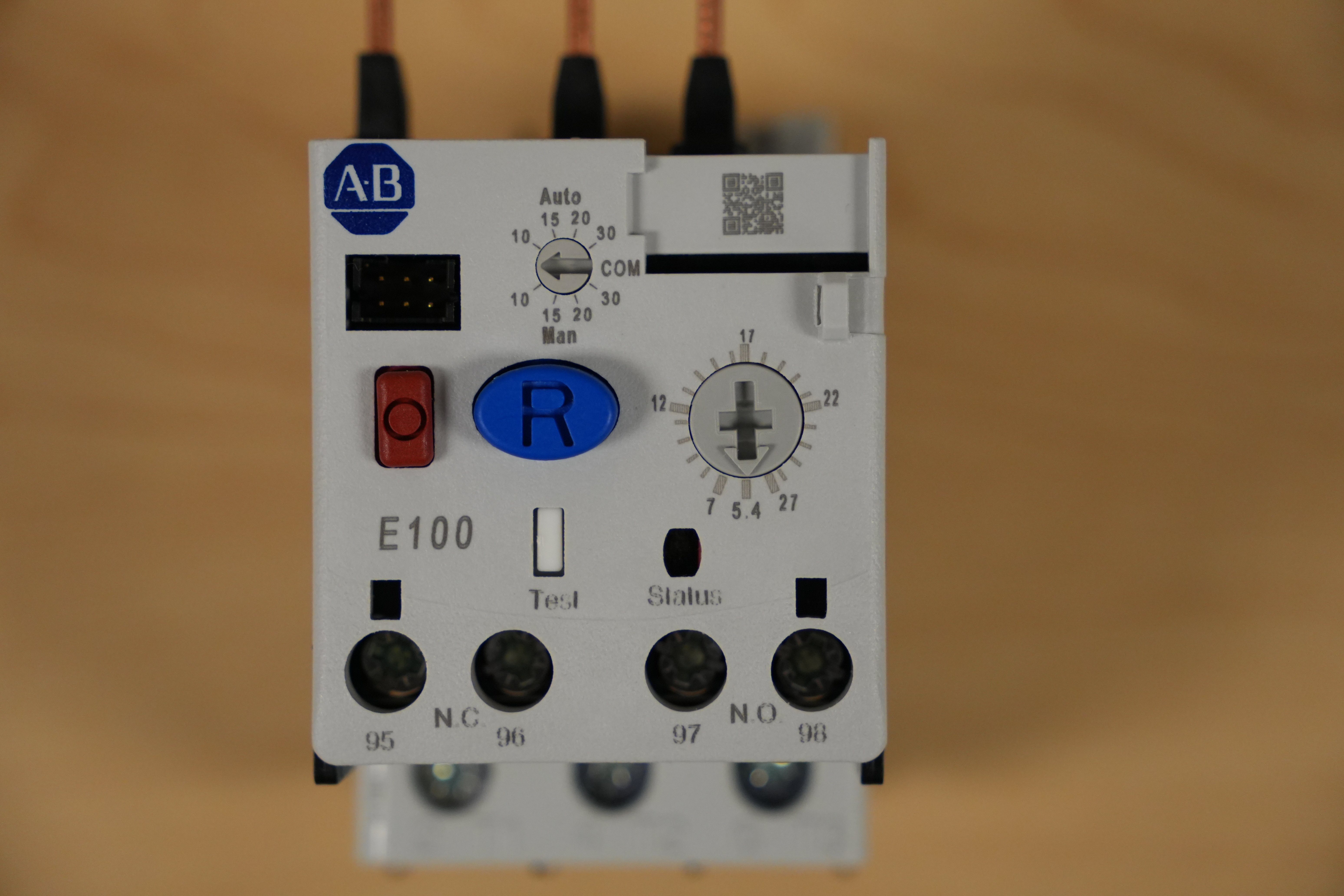

A customer recently reached out with a question that might sound familiar: they had ordered two Allen-Bradley 193-1EFEB E100 overload relays (same catalog number, same current range), but when they arrived, one included a firmware version on the label while the other did not. To make things more confusing, the adjustment dials looked slightly different.

Understandably, this raised some alarms. Were the parts still interchangeable? Did a firmware version change impact compatibility? Was this a supplier error?

In short, this discrepancy is normal, and there’s no need to worry. Below, we'll walk through why these differences occur, what you can look for, and why your equipment will still function exactly as expected.

Understanding the Differences

Both parts in this case were labeled with the same catalog number: 193-1EFEB. That means they share the same electrical characteristics, mounting style, and application range (5.4–27 A). No matter how they look externally, they're built to do the same job.

The difference that caught attention was twofold: one unit had a firmware version (1.03) printed on the label, while the other did not. Additionally, the rotary dial on the front of the unit had a slightly different appearance, as shown in the pictures below. One dial featured a bolder, more distinct typeface and minor scale marking realignment, but no function or adjustability change.

These sorts of cosmetic differences are typical across manufacturing runs and don’t affect how the part is installed or performs. The two relays are identical from a wiring, programming, and operational perspective.

The Allen-Bradley 193-1EFEB E100, Original Firmware

The Allen-Bradley 193-1EFEB E100, Firmware Ver. 1.03

Why These Variations Happen

It’s not uncommon for manufacturers like Rockwell Automation to make incremental updates to a product line, especially for devices with a long lifecycle. Sometimes these changes involve internal improvements, such as firmware optimizations or manufacturing refinements. Other times, they stem from updates to labeling or design in response to evolving compliance standards or global regulations.

In this particular case, the firmware version and the minor visual change in the rotary dial appear to stem from a temporary supply chain adjustment. Due to global sourcing challenges, Rockwell sourced components for this product from an alternate supplier. While the electrical performance and functional integrity of the part remain the same, slight differences in labeling, part aesthetics, or firmware tracking may occur as a result.

The firmware version printed on one of the relays likely reflects a small internal revision, such as a diagnostic tweak or minor production-related change, not a functional shift. These kinds of updates are routine and don’t alter how the device operates. Because they don’t impact compatibility or usage, Rockwell doesn’t issue bulletins or warnings unless the change affects the end user experience. If a firmware update did require different handling or create any compatibility risk, Rockwell would communicate that clearly through a Product Notice or Technical Data Sheet revision.

Lastly, differences like these are also a natural byproduct of mixed inventory. Distributors and manufacturers frequently ship products from different production batches. That means two parts with the same catalog number may arrive with minor label or firmware variations, but are still fully interchangeable in both function and fit.

Can You Still Use Them Together?

Yes. As long as the catalog number matches and the current range fits your application, the parts can be installed interchangeably, even if they show slightly different labels or firmware markings. The rotary dial difference in this case is purely visual; it offers no additional control or limitation on the device.

These parts are designed to meet the same functional specifications and undergo the same validation processes, regardless of firmware version. Unless your facility uses advanced diagnostic systems or software tools that depend on a very specific firmware revision, which is uncommon for standalone overload relays, you won’t encounter any compatibility issues.

Staying Confident in What You’re Using

Discrepancies in labeling or firmware can raise valid questions, especially when consistency is important in panel design or documentation. But rest assured, these parts are engineered for interchangeability, and this type of visual variance doesn’t mean there’s a mistake or that you’ve received incompatible components.

At HESCO, we make it a priority to stay ahead of lifecycle changes, product refreshes, and firmware revisions so that you don’t have to second-guess the parts you receive. If there’s ever an update that could affect functionality, we’ll share that information proactively. And if you’re ever uncertain about a part, we’re happy to verify it for you before installation.

Need Help or Want to Stay in the Loop on Product Updates?

We’re here to support you, whether that’s reviewing incoming parts, helping with product selection, or keeping your team informed about upcoming changes in the Rockwell ecosystem.

Contact our support team anytime, and we’ll make sure you’re confident in the parts you’re using to succeed. And for monthly updates on the biggest news in automation, sign up for our newsletter here.